Year:2018 ISSUE:12

COLUMN:FINE & SPECIALTY

Click:310 DateTime:Jun.22,2018

By Zhou Yang, China National Chemical Information Centre

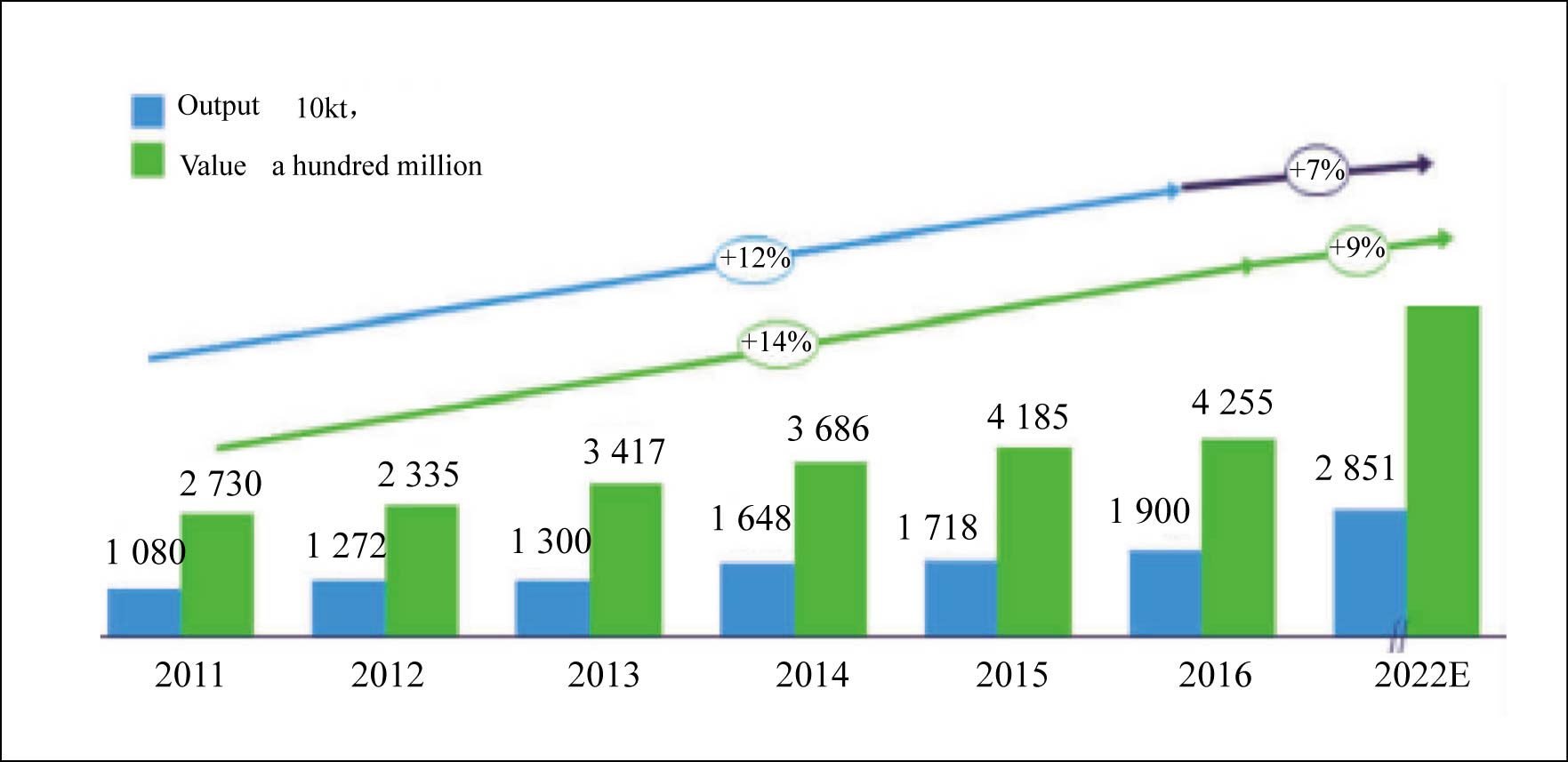

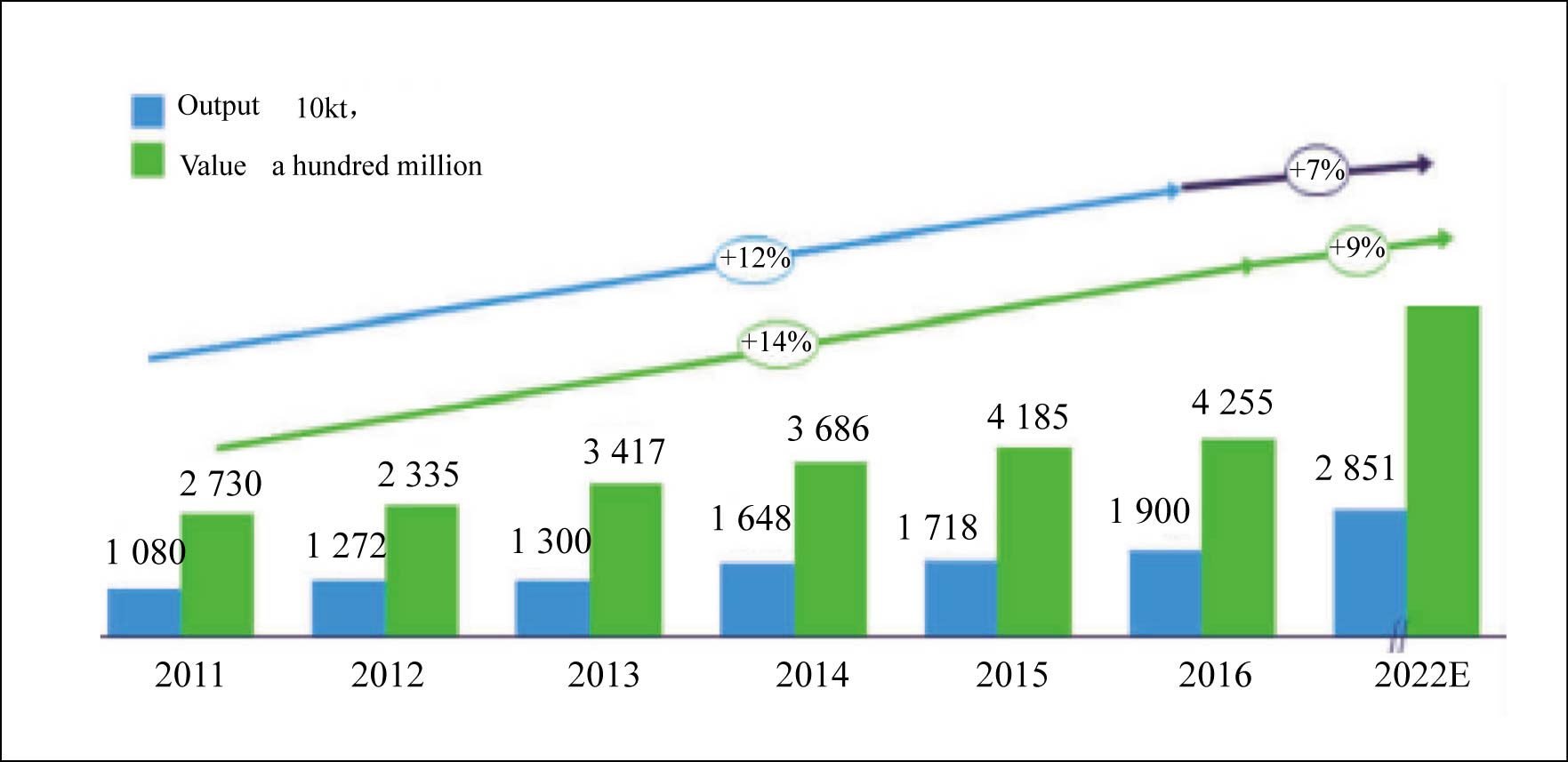

With the rapid development of China's economy and the great heat of the real estate industry, paint output in 2016 reached 19 million tons, the sales-to-output ratio was over 98% and output value reached RMB4 255 billion. The annual growth of paint output in the 12th five-year plan period (2011-2015) was 14%. Architectural coatings and industrial anticorrosive coatings grew fastest, together accounting for 62% of the total output. Growth of China's paint production is forecast to be 7% and output value growth is 9% between 2016 and 2022. The situations and forecasts of yield and output value of Chinese paints between 2011 and 2022 are shown in Figure 1.

Figure 1 Volume & value of Chinese paints output, 2011-2022

Rising environmental protection costs and intensifying market competition together make product structure adjustments and industrial transformation/upgrading inevitable trends for the industry. In 2017, the number of small and medium-sized enterprises reached 3 000. Industry concentration will gradually increase. Products are developing mainly in the direction of water-based coatings, high solids coatings, high-end powder coatings, UV-curing coatings and high-function coatings. In 2016, 46% of China’s coating output was environment-friendly (water-based coatings, powder coatings, high solids coatings and so on). According to the 13th five-year plan of the Chinese coating industry, by 2020, environment-friendly coatings will account for 57% of China’s coating output, over 10% being powder coatings, and more than 30% being water-based industrial coatings.

1. Water-based coatings

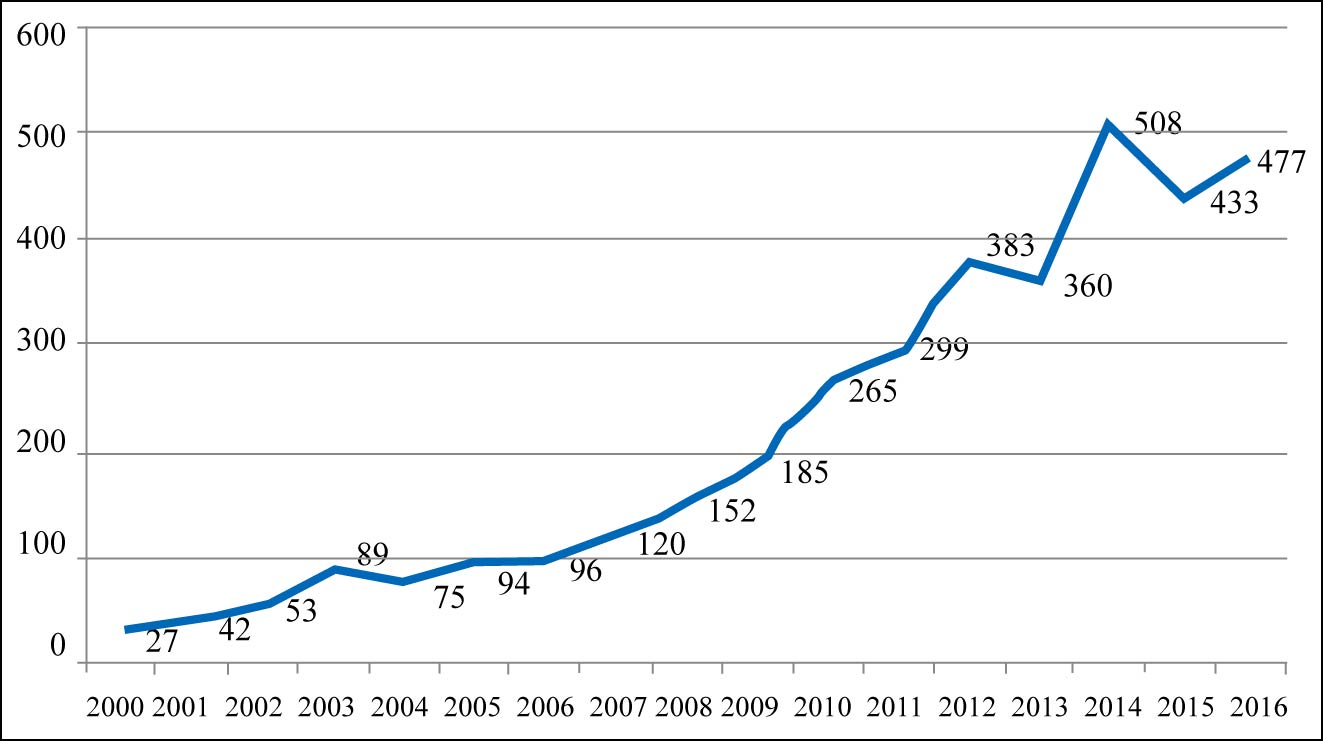

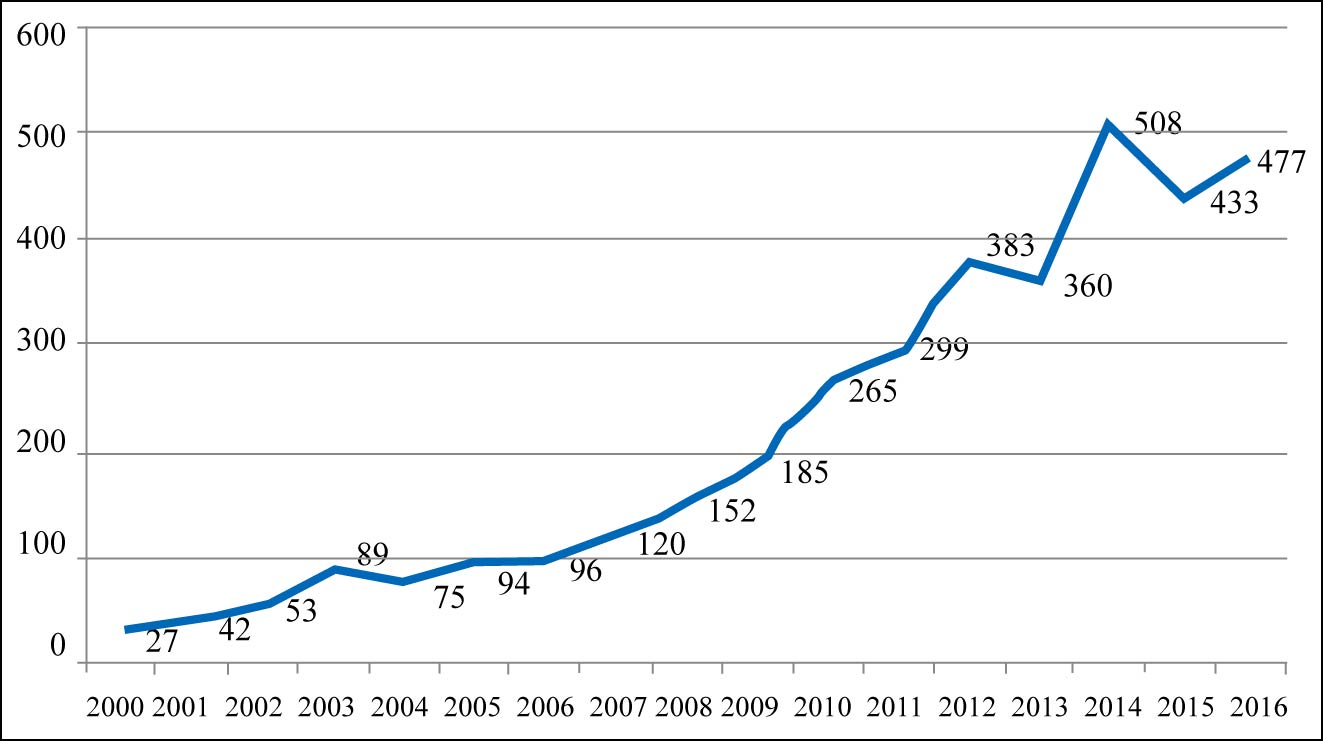

In 2016, about 1.9 million tons of water-based coatings was produced in China, accounting for 10% of the country’s coating output. In 2017, production was about 2.3 million tons, up 22%. Domestic water-based coatings are heavily used in making automobiles, steel structures and furniture. Facing increasingly stringent environmental protection policies, suppliers of raw materials, paint producers and producers of coating equipment are accelerating transformation and development around “greener” products such as water-based industrial paint. Although more than 1 000 paint enterprises have begun to shift from oil- to water-based products, most are still in a stage of R&D. The number of patents granted on water-based coatings in China between 2000 and 2016 is shown in Figure 2.

Figure 2 Patents granted on water-based coatings in China, 2000-2016

2. Powder coatings

Powder coatings are 100% film-forming material, with no volatile matter – and hence, good for environmental protection. In 2016, the output of powder coatings in China was 2.1 million tons, including about 1.42 million tons of thermosetting powder coatings, an increase of 10.1% over 2015. In the consumption of thermosetting powder coatings, 30.5% goes to the building materials sector, 22.9% to general industry and 17.2% to household electrical appliances. The proportion of powder coatings used in the building materials sector increased rapidly in 2016, while consumption for household electrical appliances and furniture declined greatly.

The main components of Chinese thermosetting powder coatings are epoxy and polyester – pure epoxy powder coatings account for about 23%, epoxy/polyester mixed powder coatings about 35%, and polyester/TGIC (or HAA) powder coatings 39%.

Both production capacity and consumption of powder coatings in China are concentrated mainly in the Yangtze River Delta and the Pearl River Delta, and many solvent coatings enterprises in this area have gradually changed over to powder coatings. Foreign powder coatings manufacturers still occupy 80% of the high-end market in China.

3. High solids coatings

High solids coatings have lower VOCs content and are better for energy conservation; moreover, their production and coating processes are similar to those for traditional solvent coatings, as are the required equipment and testing instruments. One coat of a high solids coating is 1~4 times thicker than a coat of a solvent coating. These excellent properties have promoted their rapid acceptance for automotive and other industrial coatings. In the United States, Japan and other countries, coatings with 90% solid content are used on automobiles. High solids coatings have a very broad development space in China’s automotive sector.

The main varieties of high solids coatings are amino acrylic acid and amino polyester coating, and the global development directions of high solids coatings are low-temperature curing and fast curing.

4. Other environment-friendly coatings

At present, the production of UV-cured coatings in China is small, and the main application field is wood furniture coatings, which account for more than 40% of the total output. At present, the development of light-cured coatings is also toward water-based coatings, powder coatings and other solvent-free coatings. In the future, UV-curable coatings will develop mainly toward optoelectronic devices, packaging for food and medicines, printing and so on.

Graphene is one of the most promising new materials. In high-performance coatings, the physical barrier properties of graphene can be used to improve anticorrosion, antifouling and flame-retardant effects. Using its high conductivity and high thermal conductivity, chemists can develop conductive coatings, heat dissipating coatings, electromagnetic shielding coatings and so on.

Fluorocarbon coatings have excellent weatherability, durability and chemical resistance, compared with other synthetic resins. But fluorocarbon resin is more expensive. The main direction of fluorocarbon coatings development is water-based, especially fluoroethylene based fluoropolymer modified copolymer emulsion.

In response to the national government’s increasingly strict protection of the environment, transition and upgrading is the trend of the coatings industry. Water-based coatings are the mainstream development direction of environmentally friendly coatings, but not the only way for the industry to contribute to environmental protection. Powder coatings, high-solids coatings, light-cured coatings, solvent-free coatings and so on are also environment-friendly and should be key development directions of the coatings industry.